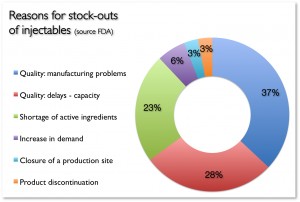

A chronic shortage of injectable drugs

Delayed surgery and suspended clinical treatments are among the dramatic consequences of an issue that has become widespread over the last few years: a shortage of injectable drugs. Faced with ever-increasing demand, producers of indispensable drugs (1) are having trouble keeping up. Numerous supply tensions have resulted at global level.

Production difficulties and, on occasion, natural disasters(protamine, which is produced from extracts of salmon fished off the Japanese coast, is no longer usable due to the Fukushima disaster) are two of the many factors responsible for this worldwide phenomenon. But management of these crucial products, particularly the supply chain policies of hospitals, also has an impact. In order to bring down costs, hospital Purchasing Groups put out calls for tender for their drugs (including injectables). The contract is awarded to a single supplier for a period of around three years. While financially this strategy pays off, the downside is a risky one. The system encourages suppliers to break the contract or simply cease production due to lack of profitability. If the supplier fails in its commitments, the hospital is left high and dry.

The time required for healthcare products to receive official approval exacerbates the situation. Taking several years, this process lengthens the time to market for drugs that could be replaced. Another damaging aspect is the externalisation of production of pharmaceutical active ingredients. Whereas 80% of these raw materials were manufactured in Europe thirty years ago, the trend has now been reversed. Mostly concentrated in Asia, these manufacturing sites make controls more complex due to the distance, and there are inevitable repercussions on the overall chain.

To counter these risks of shortages, industrial firms build up strategic stocks or implement dual sourcing. The same cannot be said of healthcare establishments. Forcing them to ration essential medication, stock-outs put their patients in serious danger (development of illnesses, longer hospitalisation, deaths, etc.).

What measures could reduce the number and severity of shortages? The example of Australia could be adopted, whereby single-supplier sourcing contracts are prohibited. Referencing of other suppliers and allowing replacement options. Similarly, a system of collaboration between the regulatory bodies would speed up accreditations and the replacement of certain products. While industrial groups have a key role to play in the prevention and management of stock-outs by reporting any failures in a timely manner, only a system in which information is shared internationally between health authorities, hospitals and laboratories would substantially scale back a problem that blights the world health system.

Sylvie Ponlot

(1) Oncology, anti-infectives, cardio-vascular diseases, the central nervous system and pain relief are the five therapeutic areas most affected.