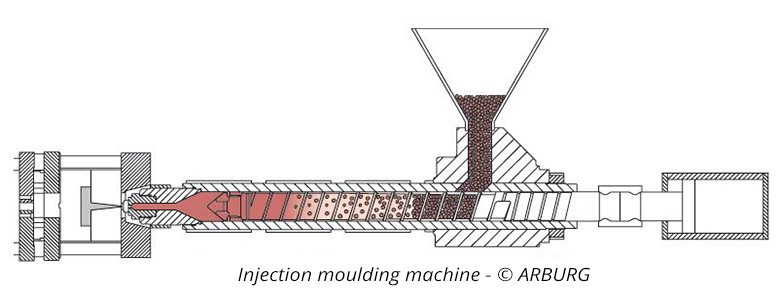

Plastic injection

Plastic injection is the historic core business of Technoflex. It is a plastic transformation technique that has been used since 1972. It involves two phases. First there is plasticization: plastic granules are poured into a hopper which feeds them into a conveying auger positioned in a heated tube. The granules are mixed there and reach their fusion point, turning into a homogenous paste due to the rotation of the auger’s screw. The second phase is injection. Under the pressure of the injection screw, the plastic fills a closed, cooled mould. As it comes in contact with the cold mould walls, it takes on the shape of the mould and solidifies. The mould then opens and the piece is ejected. The manufacturing cycle time varies depending on the shape of the piece and the material used. Starting with an open mould, the process comprises several stages: mould closure, injection of the material, pressurisation to prevent appearance defects, cooling, mould opening, and ejection of the piece.

Key figures

- 25 injection presses

- A team of 60 people

- 1 000 000 connectors produced each day at Technoflex