Controlling particle contamination, a regulatory and moral obligation

Medically, cases of thrombosis, embolism, heart attack and stroke have been attributed to the presence of particles in injectable medicines. Technoflex products are used for pharmaceutical applications, which means that particle contamination must be controlled. From the receipt of raw materials to shipping our finished products, this ever-present challenge is one of Technoflex’s priorities.

All Technoflex production is carried out in ISO Class 7 and ISO Class 8 clean rooms (as per ISO 14644-1). The air is changed 20 times per hour and filtered by multiple air treatment units with successive filtration systems (efficiency: gravimetric 85%, opacimetric 95%, and absolute 99.99%). The rooms are inspected according to a clearly-defined program, focused in particular on their rate of particle contamination. In addition to the regular measurements, an inspection under UV light is conducted each week, to validate the cleaning done over the weekend.

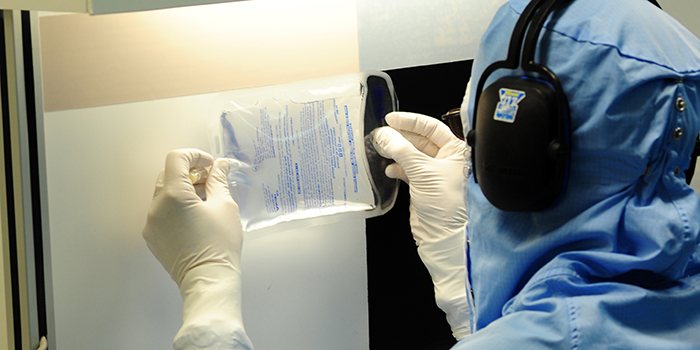

The process begins even before materials enter the clean room: received in double packaging, raw materials undergo a series of compliance checks before being released. Any questionable products are immediately isolated until further inspection. An additional special procedure is done on reels of film – the raw material used for bags – before they are brought into the clean room. The first packaging is removed in an overpressurized airlock chamber, and the second packaging is removed when the reel is positioned on the production line.

All work tools are also inspected. Computer equipment is cleaned regularly and placed in protective cabinets to prevent any contamination. The same procedures are applied to production equipment. After production, as a precautionary measure to protect them after they leave the clean room, finished products are double-packaged before being boxed and stocked in the shipping stores.

From measures ensuring the quality of the work environment, to raw material and product inspections, and internal audits… a variety of means are used to verify proper application of the prevention procedures. The quality department tracks and analyzes the results in a management chart, and this data is then used as input for Technoflex’s improvement initiative. All of these measures contribute to one common goal: ensuring the integrity and purity of our medicines for patients’ safety.

Sylvie Ponlot