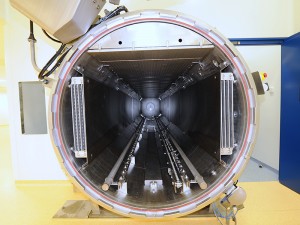

Terminal sterilization of IV bags

Crucial every time! Sterility is the absolute criterion of an injectable product. Pathogenic elements are neutralized essentially by exposure to heat (1). Autoclave terminal sterilization is essential for the safety of patients and does not allow the slightest error. A look at the risks and best practices.

Crucial every time! Sterility is the absolute criterion of an injectable product. Pathogenic elements are neutralized essentially by exposure to heat (1). Autoclave terminal sterilization is essential for the safety of patients and does not allow the slightest error. A look at the risks and best practices.

The lack of knowledge of the polymers that make up the bags or connectors can result in burst or deformed bags, damage to the twist-off or a milky appearance during terminal sterilization. But these problems can be avoided. How? First, by gaining a better understanding of the molecules’ resistance to heat, and by using sterilization methods that are adapted to the contents. But also through the perfect command of the sterilization cycle, from the temperature and the length of the cycle phases, to the pressure, the volume and shape of the bags to be sterilized, the number of bags in each load, etc.

PVC bags with over-packaging may turn white when terminal sterilization takes place in a spray or stream autoclave. This occurs when the vapor works its way between the macromolecules that make up the material. The only alternative is an air-vapor autoclave with ventilation that cools down the load.

The solution itself represents another threat. When the solution is exposed to heat, it expands and applies pressure to the walls of the bag. This pressure results in deformation that can sometimes cause the bag to burst. Regulating the pressure inside the autoclave can solve this problem.

And when it comes to the temperature, each material has its own limits. Polypropylene bags must not be heated to more than 125°C, while the limit for PVC bags is just 122°C.

There are also a few special cases. Proteins that do not tolerate severe heat, such as albumin, must be pasteurized. In this case, stream autoclaves are used to expose the solution to a temperature of 60°C for about 10 hours.

Terminal Sterilization of IV bags is a critical process in the pharmaceuticals industry that demands in-depth knowledge of all the parameters in play. Technoflex inspects and tests its IV bags under the real-life conditions of use of the products. Strict monitoring and regular checks of the autoclaves are also necessary. All new appliances must undergo initial qualification, or retrospective qualification for autoclaves that are already routinely used (2) . The conformity, quality and safety of the injectable products depend on it.

Sylvie Ponlot

(1) Apart from molecules that do not tolerate heat and are conditioned in aseptic media.

(2) GMP recommendations, Chapters 3 and 4 – §4.26 & 4.28