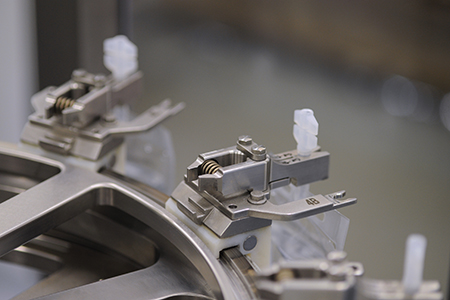

A twist-off spike port for aseptic applications

The primary packaging of an injectable solution, consisting of a bag, tubes and insertion sites, must meet the expectations of the pharmaceutical industry and healthcare personnel. It must be sterile and ensure that the system is completely impermeable. It must be adapted to the equipment used by nurses in one of the most commonly performed everyday medical procedures: the administration of drips. Indeed, many treatments are administered intravenously: antibiotics, rehydration solutions, analgesics, etc.

The primary packaging of an injectable solution, consisting of a bag, tubes and insertion sites, must meet the expectations of the pharmaceutical industry and healthcare personnel. It must be sterile and ensure that the system is completely impermeable. It must be adapted to the equipment used by nurses in one of the most commonly performed everyday medical procedures: the administration of drips. Indeed, many treatments are administered intravenously: antibiotics, rehydration solutions, analgesics, etc.

Both in the pharmaceutical industry and in the hospital environment, the importance of aseptic preparations is constantly growing. This observation led Technoflex to develop a suitable twist-off with particular advantages. First of all, its composition: manufactured in Inerta® polypropylene, it is suitable not only for the Inerta® range of bags but also any other polypropylene bag. The primary packaging of the product in PP is therefore a perfect alternative for injectable solutions which are incompatible* with PVC. Second strong point: its diameter. Although Europe has standardized drip equipment through the standard 8536-4, the latter does not apply in some countries where the pharmacopeia in use take priority. This is the case in the United States where trocars have different diameters and designs. To remedy this difficulty, the Technoflex twist-off has been specially designed to be compatible with the trocars most frequently used in North America. When it is assembled and welded automatically to the tubes or the boat ports, the twist-off meets the requirements of Container Closure Integrity Testing (C.C.I.T. is a set of tests aiming to demonstrate the integrity of the packaging and its closure in order to guarantee the sterility of an injectable product throughout its shelf life). The entire administration system, bag, tubes and insertion site, are totally impermeable to micro-organisms. It is delivered sterilized and is completely adapted for aseptic filling, whether in a hospital or industrial environment.

Sylvie Ponlot

*Physicochemical reactions such as precipitates, coloration or pH change can appear when certain active ingredients or excipients interact with the PVC.

Regulations

The latest version of the ISO 8536-4 standard, which was adopted by the European Committee for Standardisation in January 2013, specifies the requirements applicable to gravity-fed drip equipment. Its aim is to ensure their compatibility with the containers (bags or glass bottles) holding the drip solutions and with intravenous appliances.